Modern vehicles sold in the United States rely heavily on advanced engine technology to balance power, fuel efficiency, and emissions compliance. One of the most important systems supporting this balance is Variable Valve Timing, How to Masterfully Test Variable Valve Timing Solenoid 2 commonly known as VVT. At the center of this system sits a small but critical component: the Variable Valve Timing solenoid.

When a VVT solenoid works properly, it quietly adjusts valve timing to match driving conditions. When it fails or begins to malfunction, the results can range from mild performance issues to serious engine problems. Many drivers replace the solenoid without testing it first, which often leads to wasted money and unresolved symptoms.

This guide explains how to masterfully test a Variable Valve Timing solenoid 2 using practical, step by step methods. It is written for U.S. vehicle owners, DIY mechanics, and anyone who wants to diagnose engine problems accurately before replacing parts.

What Is a Variable Valve Timing Solenoid

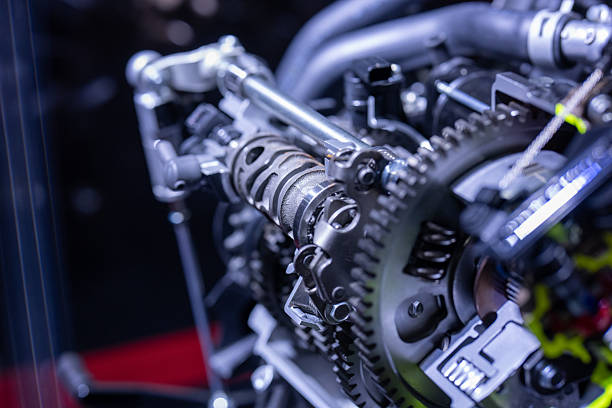

The Variable Valve Timing solenoid is an electronically controlled valve that regulates oil flow to the camshaft phaser. By controlling oil pressure, the solenoid adjusts the timing of the intake or exhaust valves, or both, depending on engine design.

In simple terms, the solenoid helps the engine breathe better at different speeds. At low RPMs, it improves torque and fuel economy. At higher RPMs, it improves power and efficiency.

Most modern gasoline engines in the U.S. use some form of VVT, including systems like VVT-i, VTEC, VCT, CVVT, and VANOS. How to Masterfully Test Variable Valve Timing Solenoid

Why Testing the VVT Solenoid Matters

Replacing parts without testing is one of the most common mistakes in automotive repair. A faulty VVT solenoid can cause symptoms that look like many other engine problems.

Testing the solenoid helps you:

- Confirm whether the solenoid is actually faulty

- Avoid unnecessary parts replacement How to Masterfully Test Variable Valve Timing Solenoid 2

- Save money on repairs How to Masterfully Test Variable Valve Timing Solenoid 2

- Prevent misdiagnosis of more serious engine issues

- Restore proper engine performance faster

In many cases, a solenoid may be dirty or electrically sound but restricted by oil sludge. Testing allows you to determine whether cleaning or replacement is required. How to Masterfully Test Variable Valve Timing Solenoid 2

Common Symptoms of a Bad VVT Solenoid

Before testing, it is important to recognize the warning signs. While symptoms vary by vehicle, the most common issues reported by U.S. drivers include:

- Check engine light illuminated

- Rough idle or stalling

- Reduced fuel economy

- Loss of power during acceleration How to Masterfully Test Variable Valve Timing Solenoid 2

- Engine hesitation

- Rattling noise at startup

- Hard starting in cold weather

These symptoms often trigger diagnostic trouble codes related to camshaft timing or oil control.

Common Trouble Codes Related to VVT Solenoids

When a VVT solenoid fails, the engine control module may store one or more fault codes. Common OBD-II codes include:

- P0010 Intake Camshaft Position Actuator Circuit

- P0011 Intake Camshaft Timing Over Advanced

- P0012 Intake Camshaft Timing Over Retarded

- P0020 Exhaust Camshaft Position Actuator Circuit

- P0021 Exhaust Camshaft Timing Over Advanced

- P0022 Exhaust Camshaft Timing Over Retarded

These codes do not always mean the solenoid itself is bad. Wiring issues, oil pressure problems, or dirty oil passages can trigger the same codes. How to Masterfully Test Variable Valve Timing Solenoid 2

Tools You Need to Test a VVT Solenoid

Testing a VVT solenoid does not require expensive equipment. Most DIY mechanics can perform these tests with basic tools.

You will need:

- OBD-II scanner How to Masterfully Test Variable Valve Timing Solenoid 2

- Digital multimeter

- Basic hand tools How to Masterfully Test Variable Valve Timing Solenoid 2

- 12-volt power source or car battery

- Safety gloves and eye protection

- Clean engine oil and rags

Optional but helpful tools include a service manual and a scan tool with live data.

Step 1: Check Engine Oil Condition First

Before touching the solenoid, inspect the engine oil. VVT systems depend on clean oil at the correct viscosity. How to Masterfully Test Variable Valve Timing Solenoid 2

Check for:

- Low oil level

- Dirty or sludged oil How to Masterfully Test Variable Valve Timing Solenoid 2

- Incorrect oil weight

- Overdue oil change How to Masterfully Test Variable Valve Timing Solenoid 2

If the oil is thick, black, or sludged, change it first. Many VVT issues resolve after a proper oil change using manufacturer recommended oil.

Step 2: Scan for Diagnostic Trouble Codes

Connect an OBD-II scanner and record any stored or pending codes. Write them down exactly as shown. How to Masterfully Test Variable Valve Timing Solenoid 2

Clear the codes and drive the vehicle for a short distance. If the codes return, it confirms the issue is active and not historical. How to Masterfully Test Variable Valve Timing Solenoid 2

Use live data if available to monitor camshaft timing values while driving. Abnormal values can indicate a solenoid that is not responding correctly. How to Masterfully Test Variable Valve Timing Solenoid 2

Step 3: Locate the VVT Solenoid

The solenoid location varies by engine design. Most engines have one or two solenoids mounted near the valve cover.

Common locations include:

- Front of the cylinder head

- Top of the engine near the timing cover

- Side of the head on inline engines How to Masterfully Test Variable Valve Timing Solenoid 2

Consult your service manual or engine diagram if unsure. Disconnect the battery before unplugging electrical connectors.

Step 4: Perform a Visual Inspection

Inspect the solenoid and wiring harness carefully. How to Masterfully Test Variable Valve Timing Solenoid 2

Look for:

- Oil leaks around the solenoid

- Broken or frayed wires

- Loose connectors How to Masterfully Test Variable Valve Timing Solenoid 2

- Corrosion at terminals

Oil intrusion into the connector is a common issue and can cause intermittent failures.

Step 5: Electrical Resistance Test

Remove the solenoid connector and use a digital multimeter to measure resistance across the solenoid terminals.

Typical resistance values range from 6 to 14 ohms, depending on the manufacturer. Always compare your reading to factory specifications.

Results interpretation:

- No resistance indicates an open circuit

- Very low resistance suggests an internal short

- Resistance outside specifications means replacement is likely needed

If resistance is within spec, continue testing. How to Masterfully Test Variable Valve Timing Solenoid 2

Step 6: Power Activation Test

Apply 12 volts briefly to the solenoid terminals using jumper wires. Listen and feel for a clicking sound.

A healthy solenoid will click sharply when energized. No click or weak movement suggests internal mechanical failure.

Do not apply power for more than a few seconds to avoid damage.

Step 7: Oil Flow and Movement Test

Remove the solenoid from the engine and inspect the oil screen.

Check for:

- Sludge buildup

- Metal debris

- Blocked oil passages

Clean the solenoid using brake cleaner or electrical contact cleaner. Do not use compressed air inside the solenoid.

After cleaning, retest electrical activation. Many solenoids return to normal operation after proper cleaning.

Step 8: Scan Tool Functional Test

Advanced scan tools allow you to command the VVT solenoid on and off while monitoring camshaft response.

Observe:

- Timing advance changes

- Engine RPM response

- Smooth transitions

If the solenoid responds correctly to commands, the issue may be elsewhere in the VVT system.

Step 9: Check Oil Pressure and Passages

Low oil pressure can mimic solenoid failure. Use a mechanical oil pressure gauge if necessary.

Common oil related issues include:

- Clogged oil passages

- Worn oil pump

- Incorrect oil filter

- Excessive engine wear

These issues are more common in high mileage vehicles.

Step 10: When Replacement Is Necessary

Replace the VVT solenoid if:

- Electrical resistance is out of spec

- Solenoid fails activation test

- Internal screen is damaged

- Cleaning does not restore operation

Use OEM or high quality aftermarket parts designed for U.S. vehicle standards.

Cost of Testing and Replacement in the USA

Testing costs are minimal if done at home. At a repair shop, diagnostic fees typically range from $80 to $150.

Replacement costs in the U.S. generally include:

- Part cost: $50 to $250

- Labor cost: $100 to $300

Prices vary by vehicle make, engine type, and region.

Can You Drive With a Bad VVT Solenoid

Short term driving may be possible, but it is not recommended.

Risks include:

- Reduced fuel economy

- Increased emissions

- Engine damage over time

- Failed emissions testing

Address the issue promptly to avoid more expensive repairs.

Preventing Future VVT Solenoid Problems

Prevention is simple and cost effective.

Follow these best practices:

- Change oil on schedule

- Use correct oil viscosity

- Replace oil filter regularly

- Avoid cheap or incorrect oil

- Address check engine lights early

Clean oil is the single most important factor in VVT system longevity.

Frequently Asked Questions

Can a VVT solenoid be cleaned instead of replaced

Yes. Many solenoids fail due to sludge buildup. Cleaning often restores normal function.

Does a bad VVT solenoid damage the engine

If ignored long term, it can contribute to increased wear and performance issues.

Is testing difficult for beginners

No. Basic tests are straightforward with simple tools and careful steps.

Will a bad solenoid always trigger a check engine light

Not always. Some failures are intermittent and only appear under certain driving conditions.

Final Thoughts

Learning how to masterfully test a Variable Valve Timing solenoid gives you control over engine diagnostics and repair decisions. With basic tools, patience, and proper testing, you can determine whether cleaning, repair, or replacement is needed.

For U.S. drivers, this knowledge helps reduce repair costs, avoid unnecessary part replacements, and maintain engine performance. VVT solenoids may be small, but their role in modern engines is significant.

Proper diagnosis always comes before replacement. When you test first, you fix smarter.