The torque specification for LS rocker arms is typically 22-24 ft-lbs. Proper torque is crucial for engine performance and stability.

To ensure strong and efficient performance of the LS engine, it’s important to torque the rocker arms to the manufacturer’s specifications. The correct torque helps in maintaining the proper valve operation, Ls Rocker Arm Torque, preventing excessive wear or damage to the components, and ensuring optimal engine performance.

Additionally, it is recommended to use a torque wrench to accurately tighten the rocker arm bolts to the specified torque setting, and following the proper tightening sequence is essential for even pressure distribution. By adhering to the torque specifications and guidelines, you can maintain the reliability and longevity of your LS engine.

Ls Rocker Arm Torque

Understanding Ls Rocker Arms

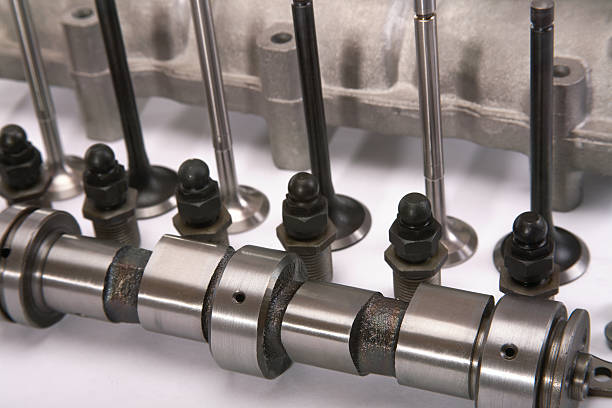

Rocker arms are a vital component of an LS engine’s valve train system, responsible for translating camshaft motion into valve movement. Understanding the components, functions, and different types of LS rocker arms is crucial for optimizing engine performance. Let’s delve deeper into this essential aspect of engine operation.

Components And Function

The rocker arm assembly includes components such as the rocker arm, fulcrum, and adjustment nut. The fulcrum pivots on the rocker stud, providing a point of contact for the rocker arm to actuate the valve. As the cam lobe moves the pushrod, the rocker arm pivots on the fulcrum, transferring the camshaft’s motion to the valve stem, allowing for precise intake and exhaust valve control.

Different Types Of Ls Rocker Arms

LS engines utilize various types of rocker arms, including pedestal mount and shaft mount designs. Pedestal mount rocker arms are secured directly to the cylinder head, while shaft mount rocker arms feature a centralized shaft to which the individual rocker arms attach.

Ls Rocker Arm Torque

Proper Torque Techniques For Ls Rocker Arms

Discover the essential techniques for properly torquing LS rocker arms to ensure optimal performance and longevity. Mastering these torque techniques is crucial for maintaining a reliable LS engine.

Proper Torque Techniques for LS Rocker Arms

Using a Torque Wrench

When it comes to installing LS rocker arms, using a torque wrench is crucial. A torque wrench ensures that the fasteners are tightened precisely to the manufacturer’s specifications. Additionally, it helps prevent over-tightening, which can lead to damage.

Applying Torque to Specifications

When tightening the rocker arm bolts, it’s imperative to adhere to the specified torque values. Failure to do so can result in premature wear or even failure of the rocker arms. It’s recommended to consult the service manual for the exact torque specifications for your specific LS engine.

Importance of Gradual Torque Application

To achieve proper torque, gradual application of torque is vital. It’s essential to evenly distribute the torque across all fasteners to prevent any stress concentrations. This helps ensure that the rocker arms are securely fastened without causing any damage to the components.

In conclusion, using a torque wrench, adhering to the specified torque values, and applying torque gradually are fundamental for properly installing LS rocker arms and maintaining the longevity of the engine.

Ls Rocker Arm Torque

Frequently Asked Questions On Ls Rocker Arm Torque

What Is The Purpose Of A Rocker Arm?

A rocker arm is a crucial component of an engine’s valve train system. Its purpose is to transfer the motion from the camshaft to the valve, Ls Rocker Arm Torque, allowing for the opening and closing of the valve at the right timing. This ensures proper intake and exhaust of gases, leading to optimal engine performance. Ls Rocker Arm Torque.

How Does Rocker Arm Torque Affect Engine Performance?

Proper rocker arm torque is essential for optimal engine performance. If the torque is too low, the rocker arm may not provide enough pressure on the valve, leading to poor valve timing and reduced power. Conversely, if the torque is too high, Ls Rocker Arm Torque, it can cause excessive wear and damage to the valve train components, impacting engine performance and longevity.

How Do You Determine The Correct Rocker Arm Torque?

To determine the correct rocker arm torque, refer to the manufacturer’s specifications for your specific engine model. Use a torque wrench to tighten the rocker arm bolts to the recommended torque value. It is crucial to follow the manufacturer’s guidelines to ensure proper valve timing and prevent any damage to the engine.

Can Improper Rocker Arm Torque Cause Engine Noise?

Yes, improper rocker arm torque can contribute to engine noise. If the torque is too high or too low, it can cause the rocker arm to not function correctly, resulting in excessive noise. It is crucial to maintain the proper torque to ensure smooth operation and minimize unnecessary noise from the valve train system.

Conclusion

To ensure the proper functioning of your engine, it is crucial to understand the significance of torque in LS rocker arms. By applying the correct amount of torque, you can prevent issues such as valve train failures and erratic performance.

Remember to consult your manufacturer’s specifications and use a reliable torque wrench for accurate results. Trusting the expertise of experienced mechanics and regularly maintaining your rocker arms will contribute to the longevity and efficiency of your engine.